As this is written in 2022, two former carpet mills located at Louther and Spring Garden Streets in Carlisle, are collectively known as the Minerva Mills. The larger mill to the west was built by E. C. Beetem and Company in 1902, and traded as Carlisle Carpet Mills. The eastern mill was built in 1914, by the Raglin Hand Craft Mills, also owned by E. C. Beetem and Son.

The firm originated in 1875 as Stephens and Beetem, a partnership that sold carpets and rugs in Carlisle. In 1882, they constructed a carpet mill on South Bedford Street and Chapel Avenue. After the death of John Stephens in 1901, his former partner, Edward C. Beetem, and his son Charles Gilbert Beetem joined with W. E. Johnson to form E. C. Beetem and Company. After Johnson’s death in 1906, Edward and his son continued the firm as E. C. Beetem and Son.

In 1906 the company started a branch mill in the Kensington section of Philadelphia. Charles Gilbert Beetem moved to Philadelphia and managed that operation. The operation was known as the Raglin Hand Craft Mills, and they produced a line of nostalgic rugs and carpets. The Raglin Hand Craft Mill prospered catering to the Arts and Crafts tastes of the times and were widely popular with consumers across the United States. Gilbert lived in Philadelphia through 1914 and part of 1915.

In 1913 it was decided to relocate the Philadelphia operations to Carlisle, and plans were made to construct a new mill. Ground was purchased from the Beetem Lumber Company, and construction was started in 1914.1

The Raglin Hand Craft Mill constructed in 1914. There are pronounced towers on each end, with an understated colonnade in the center portion of the building. Two of the panels discussed here are mounted on the colonnade. The architect is not known; however, it was designed in the Craftsman style popular at the time. Randy Watts photo, 2022.

The building is adorned with four mosaic panels featuring themes important to the Beetems and the manufacture of rugs and carpets. The mosaics were manufactured by the Moravian Pottery and Tile Works of Doylestown, Pennsylvania, owned by Henry Chapman Mercer. That fact is clearly established, but the basis of their design has occasionally been erroneously described. The mistaken identity can be attributed to an article in the Sentinel of April 29, 1914. The building had not yet been constructed, nor had the design of the panels been finalized when the article was printed; yet it is written in a manner that implies both were completed.

The construction is brick laid up in Flemish bond and terra cotta, interspersed with plaques of tile made by the Moravian Tile Works, Doylestown, Pa., which delineate the ancient art of weaving, down to the hand loom and modern loom of the present day. These plaques are hard burnt colored tile designed by Charles Gilbert Beetem, and are handmade. The ancient Assyrian, Indian, Persian and Egyptian methods of weaving are portrayed; the smaller plaques represent the ancient methods of spinning – the distaff, shuttles, bobbins, reels, and the various parts of the rug frames and looms used in primitive and medieval times.2

Fortunately, a record exists of how the design for the panels evolved, as the tiles do not include any ancient or medieval designs. The final design of the panels is documented below.

The full story of the relationship between the Beetem’s and Mercer is not documented, but it appears to have started in 1910. In a letter dated June 4, 1910, Frank Swain, the manager of the Moravian Pottery and Tile Works, wrote to E. C. Beetem & Son:

Mr. Henry C. Mercer asked me to thank you very much indeed for your kind letter and the rug, both of which came yesterday with circular, etc. He will be so very busy for the next three or four days that he will be unable to answer your letter himself before then.3

The next activity does not appear until November 1913, when Swain responds to another communications from Charles Beetem. As the design of a new building is just beginning, three panels are discussed.

Dear Sir,

Mr. Mercer thanks you for your letter and circular.

He is working on your drawing and would like to know about the size you want the three panels made in. That is, what is the size per panel. When you let him know about this, we will furnish an estimate.

Charles Beetem followed up, apparently requesting prices on a total of 8 panels at this time. Mercer, via his manager, Frank Swain, replied in a letter dated December 22, 1913.

Dear Mr. Beetem,

Mr. Mercer has been away and there has been a great rush of work so I’ve been delayed in getting out an estimate and hope you will pardon the delay. Thank you very much for your letter and drawings. If the estimate is satisfactory Mr. Mercer can go ahead with drawings for your approval. You may want to reduce the size of the panels or reduce the number of panels, etc. as the price may be greater than the sum you counted on using for the decoration. For that reason, we always send an estimate first.

My estimate is for 8 panels.

1 Panel No. 1 Crest, say 4’-0” by 4’-0”

16 sq. ft. $112.00

1 Long Panel No. 5. 8’-6” long 3’-9” high

32 sq. ft. $224.00

6 panels Nos. 2, 3, 4, 6, 7, 8 say

2’-0” x 2’-0” or 4 sq. ft.

Each $28.00 each

6 panels @ $28.00 $168.00

$504.00

The 6 panels need not be square but can be narrower and longer – to increase or diminish the area estimated on changes the cost of course but if you change the size and don’t increase the area the price is the same because we charge by the square foot.

As I said before, I am estimating on 8 panels only. You spoke of letters or memorial tablets – if they are other than these 8 panels they are not shown in the drawing and are not estimated on. The price is for mosaics set up in slabs of cement crated and delivered at our Doylestown freight station. F. O. B. cars.

In April 1914, as indicated by the newspaper article shown above, Beetem still anticipated the use of Assyrian and Egyptian figures and looms in at least some of the panels. On May 2, 1914, Mercer himself wrote to Charles Beetem:

In starting to compose the patterns for the 8 ft. long panel I think it might be better with your central panel representing Colonial weaving, to abandon Assyria, Greece and Egypt and use 1 Breaking Flax. 2 Carding Wool. 3 Spinning with distaff and spindle. 4 either reeling thread or Scutching flax.

This seems desirable because if we repeat the operation of weaving four times in antiquity, we may become monotonous in this long panel, since as a matter of fact the operation was about the same and our variation would simply come in the position or costume of the figures, while the loom would be reduced to so simple a form as not to show much variation. On the other hand, these other processes are just as ancient as the act of weaving itself, and while we might have archaeological trouble with the rearrangement of figures in costumes or the exaggeration of the later from old designs to fit this case, with the other processes we can hold to a general unity of costume and period, improving matters at the same time from a decorative point of view.

Please advise me if this idea suits you before I proceed to submit a sketch for your approval.

A letter of the same date (May 2, 1914) written by Frank Swain, addressed some other issues relating to the still pending design of the panels.

Dear Mr. Beetem,

I send you herewith a letter dictated by Mr. Mercer in reference to the designs for the large panel. Thank you very much for your letter which I have been unable to answer earlier as I wanted to take the matter up with Mr. Mercer. Will you kindly send us a copy of your commercial crest which is to be made up into mosaic for the central panel at the top. We do not seem to have a copy here with our other papers. Of course, Mr. Mercer will quarter it as per instruction in a former letter but he must have a copy to start with.

I might say here that it would be a serious mistake to build these panels in with the wall, as it is put up, as they would be damaged, I feel sure. We have found that it is much better to leave a hole or recessed space in the wall so these panels, set up in slabs with cement backing when they leave the pottery, can be inserted at the last moment. Two or three times the panels were injured or destroyed in large buildings in the west, so that anything in this nature is not put up till the scaffold is ready to be taken down, or not at that time if the rough work on the outside of the building is not finished. In leaving an opening for the mosaics you should count on two inches at least for the slab, plus the cement mortar necessary to set same in place – that is the slab that leaves the pottery will be two inches thick at least.

On May 4, 1914, a week after the Sentinel article (see above) was printed, Beetem replied to a letter from Mercer discussing the design of the mosaics. He wrote as follows:

Dear Mr. Mercer,

Suggestion for the entire 8-foot panel as contained in your letter of 2 May is, unquestionably, the right thing to do, i.e., keep this entire plaque on the colonial and show various operations: 1. Breaking Flax; 2. Carding Wool; 3. Spinning with Distaff and Spindle, and for the 4th, will you permit me to suggest Weaving on the hand loom.

It strikes me this latter will perfectly complete the series and is most important.

Possibly an ancient Assyrian or Egyptian motif could be placed in the two smaller spaces that are about 2 feet square.

Herewith enclosed is stationary showing several different Bees of the crest of the firm. I believe your original idea (which appealed to me very much) was to place this crest to the top, with the words “quality” somewhere and the firm name; and beneath, to quarter same, showing spinning wheel, in one corner; shuttles, distaff, bobbins, or reed, or something applying to weaving in the other quarters.

Any time you desire to consult me personally, I will drive up.

With all good wishes, C. G Beetem.4

Mercer replied to Beetem on May 6, 1914 (the mail was a lot faster then.):

Dear Mr. Beetem,

I send you a few, off hand sketches showing the proposed arrangement of the large plaque with the five panels and the Arms with quartering. The two other plaques will best be based on the wool and flax spinning drawings that you already know and say you like which I think would be altogether appropriate.

As in the arms we have a rather large field I thought it would be well to introduce as many quarterings as possible so I have shown the bees twice, a spider with its web, spindle, distaff, spinning wheel, hatchel, scutching knives with the crest in the middle. I have also made the outline of the shield prominent to give it an armorial effect which it might lose if we simply set the emblazonment in the recess left by the architect.

As to the large panel I threw in scutching with the knives to the extreme right as probably showing more action than we would get from a figure bending over a table working the heddle frame or little garter loom. Moreover, in that case the action is after all only that of the large loom in miniature while scutching is a very striking operation from a decorative point of view and also very characteristic of Colonial days and textile work.

Nevertheless, if you insist, I will throw out the scutcher and put in the man with the Heddle frame, though I would rather not. Remember these are simply preliminary splutterings. I did not think that you wished me to work up finished drawings to scale. Nevertheless, if you say go ahead, I will send you bulletins of these as we proceed. Hoping that I may be able to please you, I am,

Sincerely yours,

H. C. Mercer.

Based on the updated design, Manager Swain sent an updated quotation on May 7, 1914. (Swain seems to have always been in a great rush.)

Dear Mr. Beetem,

In the great rush to get letter and drawings to you I neglected to send an estimate for said work.

The crest space is larger than that estimated on originally so it costs more. The long panel is longer but not quite so high so it costs less.

The 2 little panels are a shade larger but I have counted them the same as on original estimate.

1 Crest panel 21 sq. ft $147.00

1 Large panel 30 sq. ft. $210.00

2 Smaller panels 8 sq. ft. $56.00

$413.00

The mosaics would be set up on slabs here with cement backing ready to insert in place. Crest may have to be in two pieces. Large panel in 2 or 3 small mosaics would be set in one piece. We would cast all pieces as large as possible to insure safe carriage, etc. Prices F. O. B. cars Doylestown.

Hastily yours,

Moravian Pottery.

At this point the design of the large panel and the two small panels was agreed to. But some issues remained with the design of the crest panel. Frank Swain addressed the issues related to the crest in a letter dated May 12, 1914.

Dear Mr. Beetem,

Mr. Mercer asked me to thank you for your order and to say that is seems impossible to insert the firm name in the shield plaque without doing severe damage to the shield. To get the name in so it looks well would mean a lot of scrolls built into the shield space and to do this would reduce the other things so much that it seems a pity to spoil the effect. He notices there is quite a large brick space directly underneath so you would have ample room to treat the name as a separate panel. Don’t you think this would be much better – if so, please state about how large a panel you think would do.

The shield panel is already drawn and to add anything would mean an entire new arrangement. We can let you know at the proper time the colors (unreadable) as you would see them would probably mislead you because the color of unburnt clay is quite different from finished burnt clay – a lime white goes blue – a pink goes yellow, etc., and Mr. Mercer counts on burning and reburning pieces until he gets something pleasing and even he at this moment does not know that the colors as arranged by him will look well without being changed two or three times. That’s the reason we should have ample time on all mosaics and I am glad you see your way clear to grant this.

Moravian Pottery, per Swain.

The Beetem’s elected not to purchase any additional tiles or plaques at this time.5

The panels were done by June 19, 1914, and Swain offered Charles Beetem the chance to stop by and inspect them in a letter of that date. He offered to ship them at that time, but they were not shipped until July 3, 1914. The long panel was made in five sections, while the crest was laid up in two panels. In the meantime, an issue with the size of the panels arose. Swain wrote to Beetem on July 1, 1914, to discuss their size.

Gentlemen,

In ref. the mosaic panels. These were made very carefully, dried slowly, and burned with great care in order to produce the very best colors. As most orders are hurried – dried quickly and burned quickly, there is a deal of shrinkage we must allow for over and above the finished size. Yours did not shrink down as much as we counted on and set up, they are now 42 high instead of 40 ¾ which is the size of the space on the blue print or 1 ¼ inches too large. Can you care for this in running up the bricks making the panel opening 42 inches high? Of course, a row of bricks at the top can be cut for the insertion of the panel there making the brick space above the panel almost equal with that below. The length of the panel is all right – also the two square ones.

Hastily and truly yours,

Moravian Pottery.

The panels were shipped via the Reading Railroad, and were loaded at Doylestown, Pa., on July 3, 1914. The shipment consisted of 9 crates with a total weight of 1925 pounds. The shipment would have arrived at the Reading freight station on East High Street; but the date of arrival is not known. The panels and the bill must have arrived before July 8, 1914, as on that date Manager Swain replied to what must have been a complaint made by the Beetems concerning the charges for the panels.

Dear Mr. Beetem,

I have your letter in re. advance charges on mosaics over our estimate to you Dec. 22 13 – in which you think our bill sent a few days ago is wrong. I have gone over the matter carefully and find that the estimate Dec. 22 13 was for mosaics of the size you quoted at that time – in the rough I might say. Hence my note stating that you might change the shape, increase or lessen the area and that the price would increase or lessen accordingly – then the matter dropped.

Then you sent us exact sizes of the openings April 28-14 and we worked out a new estimate according to these openings and sent it to you January 7-14 as follows:

Crest panel – 4’ 11” wide

4’9 ¼ “less corners – 21 sq. ft $147.00

Large panel 8’11” x 3’ 4 ¾ “ $210.00

2 small panels 2’1” by 2’ ¼ “

Or 4 sq. ft. each $56.00

$413.00

Slabbed. F. O. B. Doylestown in crates.

On May 8 -14 – you wrote:

No. 1 The sketches you kindly sent me came to hand this a.m. Also, your letter containing revised estimates which is satisfactory. No. 2 Please proceed right ahead with the work., etc., etc.

You see my estimate Dec 22-13 called for a shield or crest 4’ x 4 feet or 16 ft. The shield sent measures 4’ 9 ¼ “x 4’ 11” less corners – that is 9 ¼ inches by 11 inches larger than the original estimate. The large panel estimated as 8’ 6” x 3’ 9” in the original estimate was reduced to 8’ 11” x 3’ 4 ¾ “and while the two smaller panels were increased a very little the old price remained the same.

If you will kindly look up my letter, estimate of May 7-14 and your reply May 8 – you will find that our bill is for the revised and accepted estimate – accepted by you before we started to do the work.

Your letter yesterday worried me considerably for I hate to think that I overcharged anyone but I am glad to find same ok. Will you kindly let me learn that you find this correct?

Moravian Pottery – Swain.

Apparently, Swain’s letter resolved the issues concerning the amount of the invoice, but for whatever reason the Beetem’s did not pay it within the 60-day terms. On October 6, 1914, Swain penned them a polite letter reminding them of the open bill. The Beetems sent a check for $213.00 on October 13, 1914 and promised to send the remainder in “several weeks.” Swain agreed to the terms. An internal memo on the bill notes that the tiles were not included in the contract with the builder. The final installment of $200.00 was paid on December 11, 1914. E. C. Beetem added a note to Mercer thanking him for his leniency in awaiting the payment of the bill.

This, with the exception of examining the mosaics, completes the story of the evolution of the design of the decorative panels on the Raglin Hand Craft Rug Mill. The history of the E. C. Beetem companies is told in the book The Industrialization of Carlisle 1750 - 1920, Volume 1 – Carlisle’s East End, published in 2022 by Randy Watts.

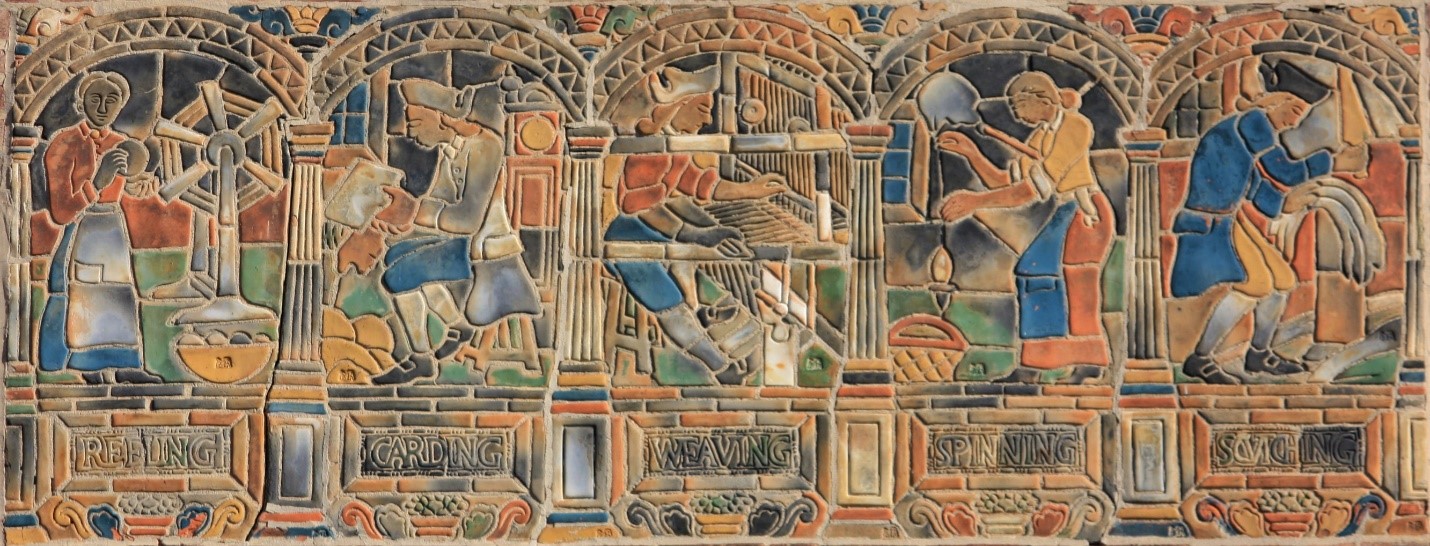

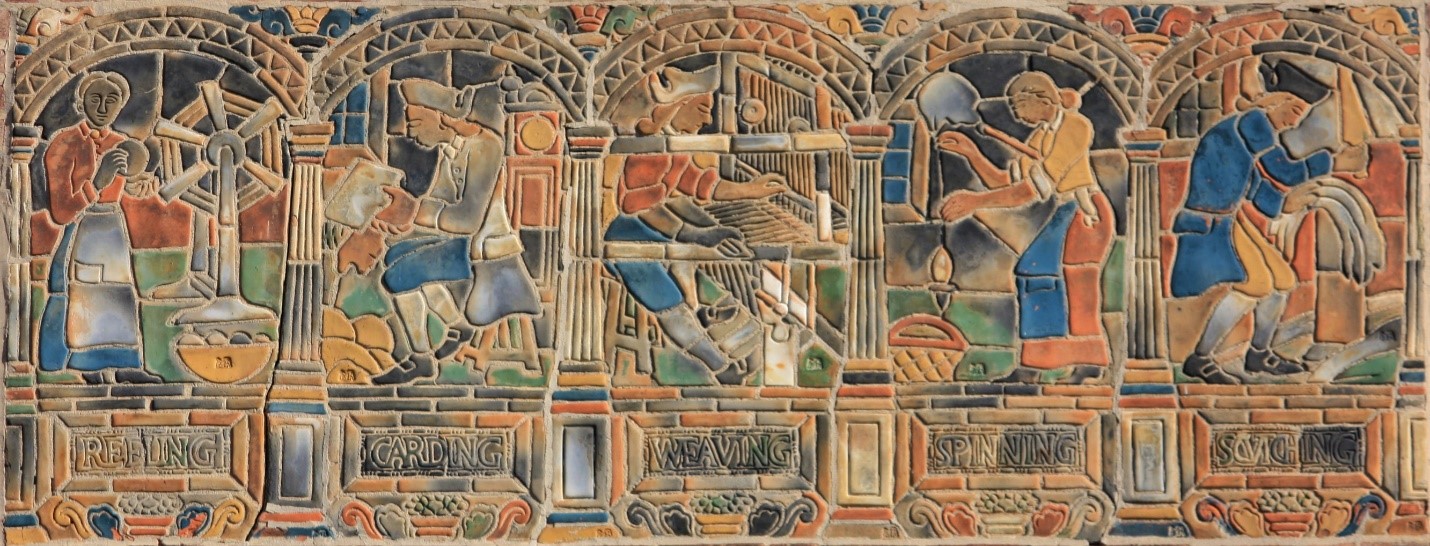

The main panel on the colonnade in the center of the building. From the left: Reeling, Carding, Weaving, Spinning, Scutching. Scutching was the initial step in the process and involved striking the flax with a “scutching knife,” to remove dirt and prepare the fibers for use. The panels do not sequentially follow the steps involved in converting fiber to fabric. Randy Watts photo 2022.

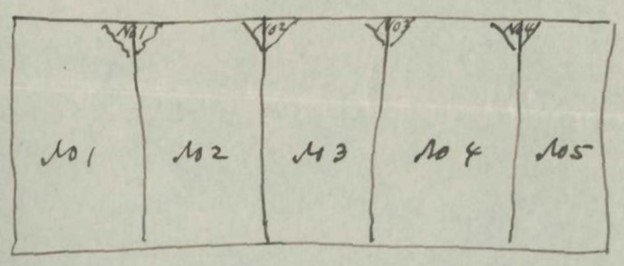

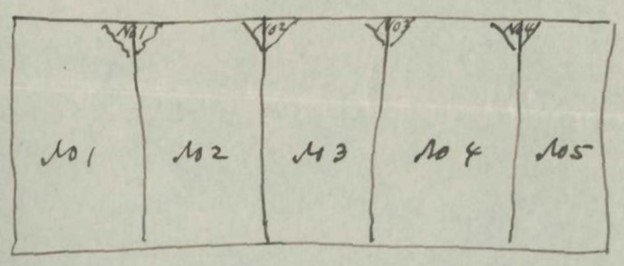

The sketch showing how the panels were to be assembled with a notation on the small pieces that were separate from the main panels. For additional information see the text below.

A close up of the triangular pieces between each of the five panels on the long mosaic. Randy Watts photo 2022.

The large panel, as noted, is actually comprised of five smaller sections. The small triangular pieces between each panel were not part of the main panels. Swain described the reasons for this in a letter dated July 3, 1914.

The little triangles at the top between the arches were set with the tiles but came loose after all so they will have to be set in carefully with a joint as close or tight as possible. They must be unpacked and handled carefully but when once fast in the wall nothing can harm them – and be sure to locate all the triangle pieces for the top of the large panel before destroying the paper, etc., they are packed in.

They are not yet dry; the chemical action of the cement may send out a gray frost like sediment or effervescence – this can be sponged off at the last minute before the scaffold comes down. Let them get good and dry.

There are two smaller panels in the center of each wing of the building between the 2nd and 3rd floors. The west image is at left. These are the panels that Charles Gilbert Beetem had originally wanted to feature ancient motifs. Randy Watts photos 2022.

|

|

The “Crest” of E. C. Beetem & Co. This served as the basis for the design of the “crest,” or as Mercer seems to have called it, the “shield.”

|

The “Crest” located at the top of the colonnade. The arm holding the sword in the center is from the “crest” of E. C. Beetem and Son. Randy Watts photo 2022.

The Raglin Hand-Craft Mills building also features some unique terra cotta or cast concrete work and hand-crafted lights. Many of these details are obscured by modern day signage. Randy Watts photo 2022.